Our Services

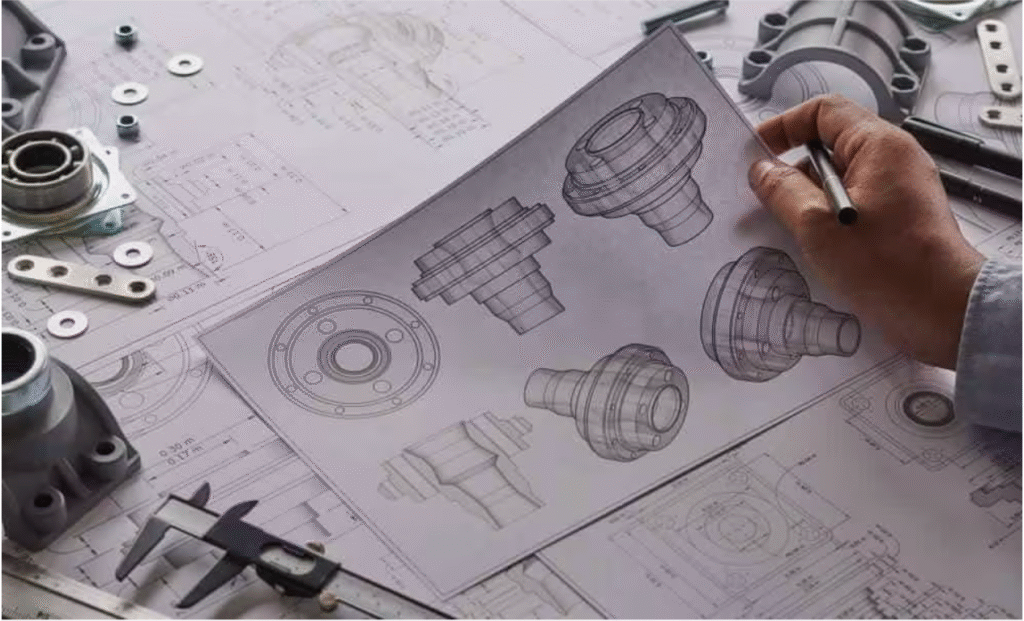

2D Drafting with GD&T

Mechanical 2D drafting with GD&T (Geometric Dimensioning and Tolerancing) is essential for accurately defining the size, form, orientation, and location of features on mechanical parts. This advanced drafting method ensures clear communication of design intent and manufacturing precision. Our company specializes in providing high-quality 2D drafting services with GD&T, delivering detailed and standardized drawings that meet industry requirements. We help clients achieve greater consistency, improve quality control, and reduce production errors through precise documentation.

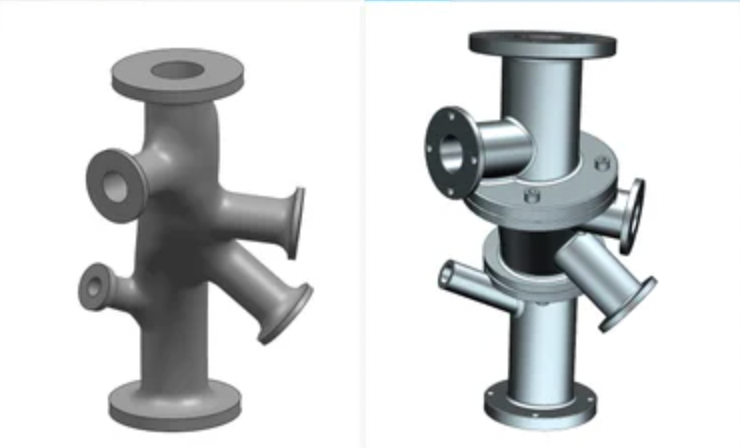

Solid Modeling

Mechanical solid modeling is the process of creating detailed 3D digital representations of mechanical parts and assemblies. It allows for accurate visualization, analysis, and simulation of components before manufacturing, helping to identify design issues early and streamline production. Our company offers expert mechanical solid modeling services, using advanced CAD tools to develop precise and functional 3D models tailored to your project needs. We support innovation, reduce prototyping costs, and enhance design efficiency through our professional modeling solutions.

Surface Modeling

Mechanical surface modeling involves creating complex and detailed 3D models that focus on the contours and surfaces of a part, rather than its volume. This technique is ideal for designing components with intricate shapes, such as automotive bodies, consumer products, and aerospace parts. Our company offers specialized mechanical surface modeling services, delivering high-precision models that meet both aesthetic and functional requirements. With advanced CAD tools and experienced designers, we help bring your most challenging surface designs to life.

Product Design

Mechanical product design is the process of developing functional and manufacturable mechanical components and systems, from concept to final design. It involves innovation, engineering analysis, material selection, and detailed CAD modeling to ensure performance, reliability, and cost-efficiency. Our company provides comprehensive mechanical product design services, transforming ideas into practical, ready-to-manufacture solutions. With a focus on quality, precision, and client collaboration, we deliver designs that meet technical requirements and market demands.

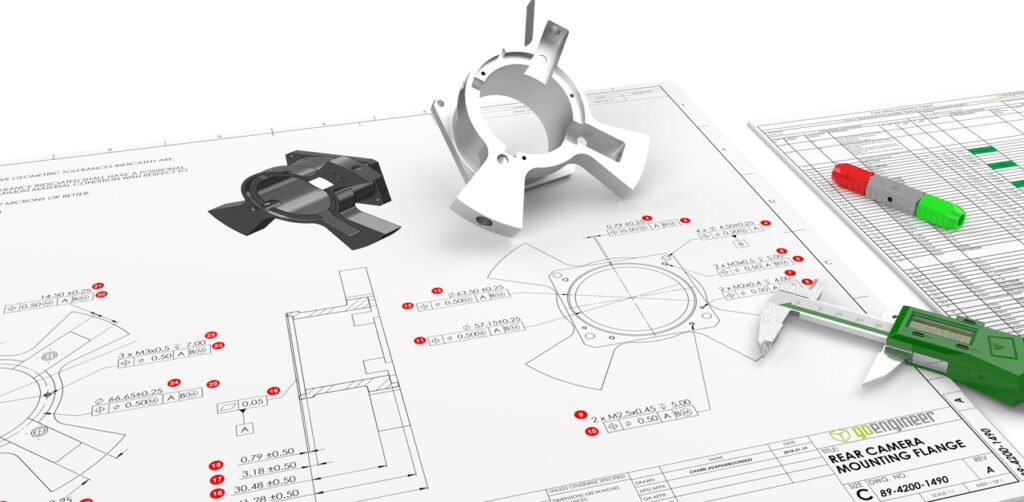

Inspection Reporting

A mechanical inspection report documents the evaluation of mechanical parts or assemblies to ensure they meet specified design and quality standards. It includes detailed measurements, tolerances, visual inspections, and compliance with technical drawings and specifications. Our company offers professional mechanical inspection reporting services, providing accurate and thorough documentation to support quality assurance and regulatory compliance. We help clients verify part integrity, reduce defects, and maintain high manufacturing standards.

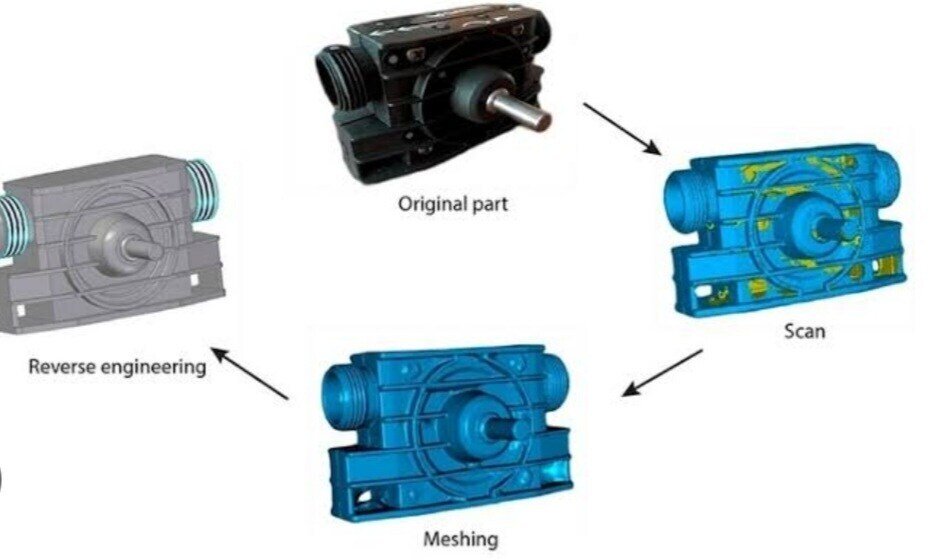

Reverse Engineering

Mechanical reverse engineering is the process of analyzing and recreating existing mechanical parts or assemblies to develop accurate digital models and technical documentation. This is often used for legacy components, replacement parts, or design improvement. Our company offers expert mechanical reverse engineering services, utilizing advanced tools such as 3D scanning and CAD modeling to capture precise geometries and specifications. We help clients rebuild, optimize, and modernize components efficiently and cost-effectively.

Mold Design

Mechanical mold design involves creating detailed 3D models and technical drawings for molds used in manufacturing processes such as injection molding, die casting, and thermoforming. It requires precision engineering to ensure optimal part quality, efficient production, and mold durability. Our company provides professional mechanical mold design services, delivering high-performance mold solutions tailored to your product and production requirements. With a focus on accuracy and manufacturability, we help streamline the tooling process and reduce production costs.

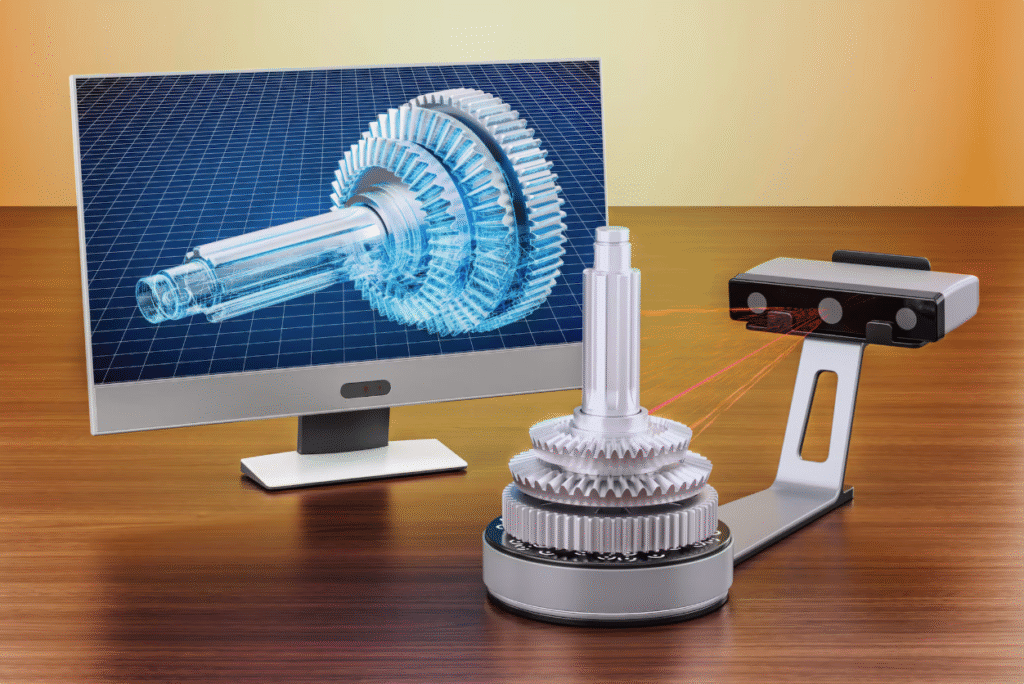

3D Scanning

Mechanical 3D scanning is a precise method of capturing the exact shape and dimensions of physical objects to create accurate digital models. It is ideal for quality inspection, reverse engineering, and product development. Our company offers professional mechanical 3D scanning services using advanced scanning technology to deliver high-resolution, detailed data. We help clients digitize components quickly and accurately, enabling better analysis, redesign, and integration into CAD systems.

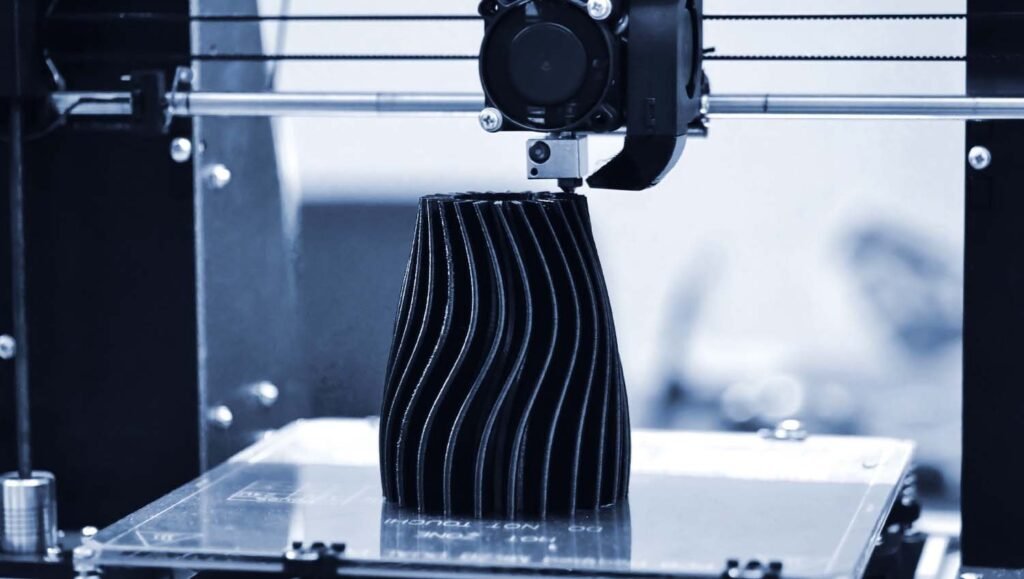

3D Printing

Mechanical 3D printing using SLA (Stereolithography), FDM (Fused Deposition Modeling), and SLS (Selective Laser Sintering) technologies enables the rapid production of functional prototypes and end-use parts with varying levels of detail, strength, and material properties. SLA offers high-resolution parts with smooth finishes, FDM provides durable and cost-effective models, and SLS creates strong, complex geometries without support structures. Our company provides comprehensive mechanical 3D printing services across these technologies, delivering tailored solutions to meet your design, testing, and production needs with speed and precision.

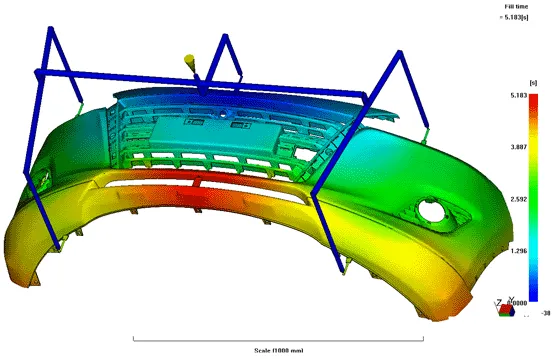

Mold Flow Analysis

Mechanical mold flow analysis is a simulation process used to predict how molten material will flow within a mold during manufacturing, helping to identify potential defects such as air traps, weld lines, and warpage. This analysis is essential for optimizing mold design, improving part quality, and reducing production costs. Our company offers expert mold flow analysis services, using advanced software to provide accurate, data-driven insights for efficient and defect-free molding. We help clients enhance their tooling performance and ensure reliable, high-quality results.